- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

box feed powder coat machine

Product explanations:

It is good for quick and easy color changes,It is designed to use the powder

manufacturer’s original carton.

An inclined vibration table allows complete emptying of the powder box via the

fluidized suction tube.

0-100 Digital Adjustable KV

Fully Adjustable Amperage

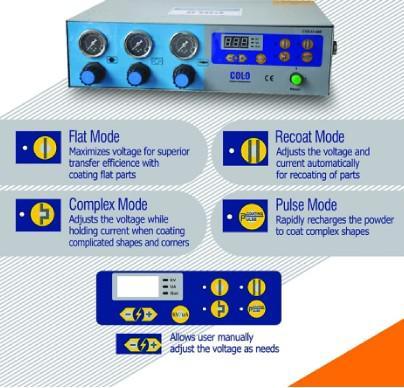

With three setting program,for flat shape workpiece,complicated shape workpiece,recoating,easy for operation.

Fully Adjustable Air for Pump on Pressure, Dosage and Nozzle Rinsing Air.

Comes with Full Array of Nozzle Assortment.

Field Tested and Proven to operate in the toughest environments.

Comes with different array of delivery systems:

Because this system is specially balanced for the maximum spray capability with

the Smoothest Finish Possible.

Product features:

pulse power plus intelligent function ,it do good jobs for

different metal workpieces such as flat ,recoating or complex shapes .

→FUNCTIONS

.The fluidzed powder in the powder original box is sucked up in the injector by the conveying air. Through the powder hose the powder air mixture reached the gun

.The powder is electrostatically charged immediately it reaches the gun nozzle.An intense field also exists between the gun nozzle and the grounded workpiece. The electrostatically charged powder sprayed onto the workpiece adheres to the latters surface.

.This line voltage is converted in the control module to high –frequence current

this currents stpped up by the high-voltage transformer and the HV-cascade in the gun to 100KV and applier to the electrodes.

.The converying air and the dosing air is to be requlated on the control module , the fluidizing air on the peneumatic unit.

.The powder is fluidized by forcing air from bleow through a proous plastic plate.

.The fluidized powder gets liguld –like properties.

→Technical Data

Power range 100-120v

Frequency 50/60HZ

Temperature range in use -10 ℃+50 ℃

Powder Gun

Gun weight: ……………… 500G

Rated output voltage ……… 24VDC

Input voltage …………… - 200kv

Maximum output current ……… 180Ua(max)

Maximum output voltage………… 0-100KV ( adjustable)

Maximum powder injection :……… 600g/min

Polarity ……………… negative (-)

Pneumatic technical spec

Maximum input-air pressure ………….. 8kg/cm

Optimum input-air pressure…….. 6kg/cm

Minimum input-air pressure …… 4kg/cm

Maximum water vapor content or compressed air ….. 1.4g/N m3

Maximum oil vapor content of compressed air …….. 0.1ppm

Maximum cimpressed-air consumption……… 13.2 m3/h

TPulse coating ………….. ………….. ………….. 15~20 clock/sec

COLO-660V

COLO-660

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content