- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

bitty pulse powder spray gun

bitty pulse powder spray gun

aluminum profiles pulse powder spray gun

Manual hopper feed unit

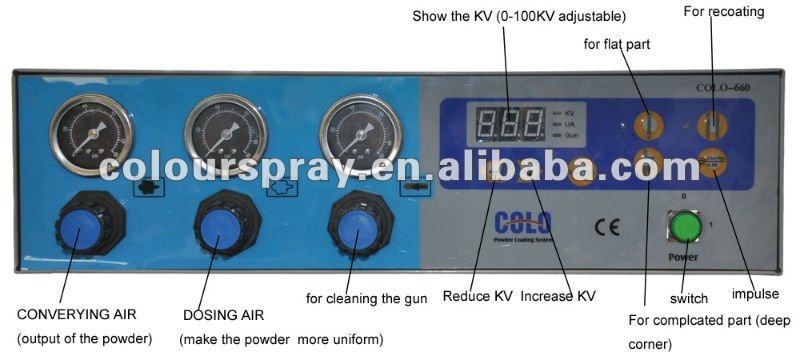

Digital display powder spray equipment

touch key

Suitable for heavy duty work

manual powder coating machine

Pulse Powder coating system technology provides excellent transfer efficiencies, superior powder penetration, and a quality finish with no gun adjustments needed.

Powder feed system with air purge for faster, easier maintenance.

Modular hopper disconnects without tools.

1,Digital control system,display preset Voltage and currency at the same time.

2,Preset Voltage and currency be setted by knobs, easy to operate.

3,Alarm automatically if over the preset parameters

4,Adjust the outputstatic electricity automatically according the change of workpiece’s size and distance

5,Could supply large amount powder under low pressure.

6,The inside circuit region is Independent sea, avoiding the powder incoming.

7,Good quality pressure gauge

8,Good quality dust-proof powder switch

9,Control the useless power strictly,low heating value,work continuously and steadily.

Electrical data

Mains input voltage: 220V/110V

Operating frequency:50HZ /60HZ

Powder:50W

Output voltage (to the gun):0-100KV ( adjustable)

Maximum output current (to the gun): 180UA(max)

Protection type:IP54

Approvals:CE Certification

Pneumatical data

Input pressure: min. 6 bar(87PSI)/max. 10 bar(145PSI)

Recommended input pressure: 7 bar(101.5PSI)

Max. water vapor content of the compressed

air 1.3 g/m³

Max. oil vapor content of the compressed air 0.1 mg/m³

1. CE certificate

2,powder hopper

manual powder coating equipment

built-in high voltage electrostatic generator

1. Powder applicable:

All coating powder specially for metal powder

2. Configuration:

Host = 1 pc

Powder Spray Gun = 1 pc

Powder hopper = 1 pc

Trolley = 1 pc

Powder pump = 1 pc

Oil-water separator = 1 pc

Air pressure regulating valve = 1 pc

powder coating gun, powder coating machine, powder coating system,powder coating equipment,powder coating control unit

The process of the coating is like this :the powder isfluidized in the powder hopper. The injectorstransport the powder through the hoses to the guns . The guns spray a powder/air mixture onto the workpieces.

COLO Powder Coating Systems is a top supplier of powder coating machine and powder coating equipment including automated equipment, spray booths and spare parts famous brand in china.

- Mobile Phone

- *Title

- *Content

- Mobile Phone

- *Title

- *Content