- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

powder spray booth /powder machine /powder coating system

Manual Electrostatic powder spray equipment ,Includes powder coating cabinet , Electric or Gas Powder Oven, and manual powder coating gun. We have the most popular configurations available and please contact us for special combination you do not see posted.

1,The spray booth specification as follow:

Electrostatic powder spraying booth

The powder booth fans draw air through filters and releases it through the top of the booth. It keeps your shop nice and clean,minimizing powder dust.

Benefits of our powder booth

- Operator Safety

- Environmental compliance

- Production capacity and operational efficiency

- Color changeover

- longer lasting, more durable, quieter

include fans, motors, nut and bolt fasteners, filters, detailed drawings and instructions, all included in one single shipment.

Data:

| Model | COLO-S-1301 |

| Booth Type | Closed |

| Operator dimensions | 700width x 1000 height x 800 depth |

| Overall dimensions | 1000width x 1900 height x 1600 depth |

| Weight | 150kg |

| Power supply | Electric |

| Nominal power | 1.5kW |

| Voltage | 380V |

| Frequency | 50-60Hz |

| Filters | Polyester |

| Filters count | 1 |

| Filters hang type | easy for change |

| Filter cleaning system | Pneumatic |

| Air consumption | 5100m3/h |

| Warranty | 12 months |

During operation overspray powder accumulates on the cartridge filters. As the cartridge filters load, airflow decreases and the negative pressure rises within the air handler. A timer activates a system of air purging valves that clear the cartridge filters of the accumulated powder to ensure maximum flitter life.

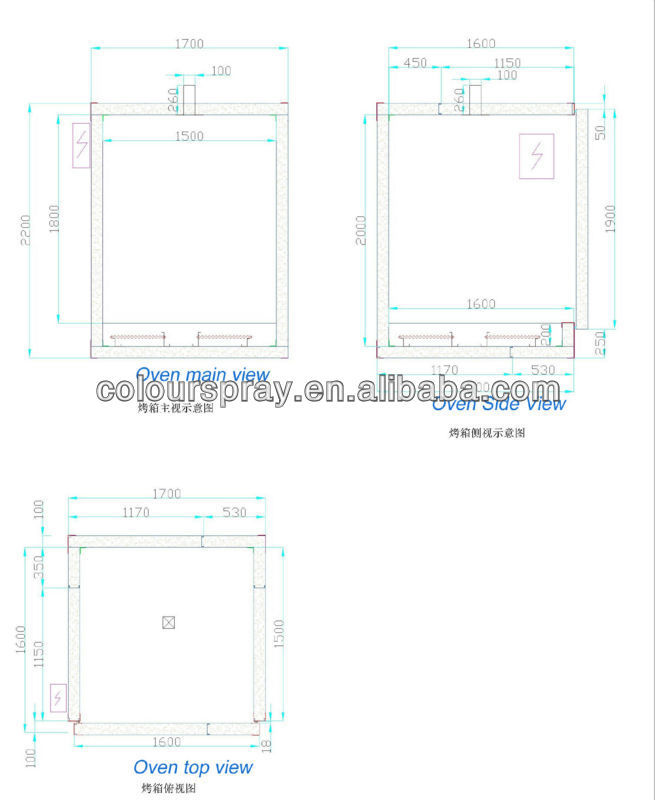

2,This Powder coating oven

for curing the workpiece which has been spraying during the powder coating. When a thermoset powder is exposed to elevated temperature, it begins to melt, flows out, and then chemically reacts to form a higher molecular weight polymer in a network-like structure.

- Structure:consist of Body,insulation, cover, heater. use electric to create the energy ,through the circulating fan ,make the temperature in the oven to rise uniformly. Then make the temperature of workpiece to rise.

built-in track to roll your powder coating racks into the ovens could be ordered together as you required.it is free.

Drawing:

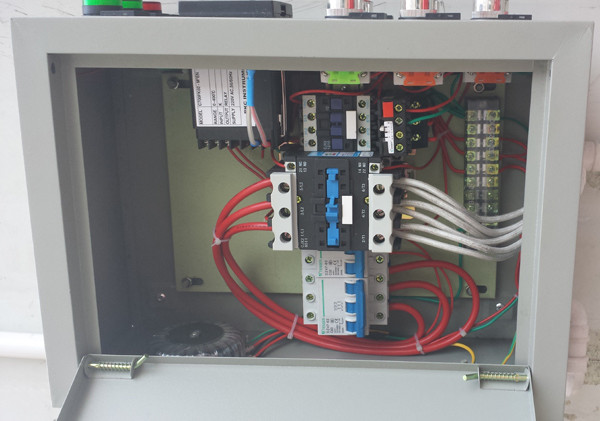

3,Manual powder coating system

CL-131S

0-100 Digital Adjustable KV

Fully Adjustable Amperage

With three setting program,for flat shape workpiece,complicated shape workpiece,recoating,easy for operation.

Fully Adjustable Air for Pump on Pressure, Dosage and Nozzle Rinsing Air.

Comes with Full Array of Nozzle Assortment.

Field Tested and Proven to operate in the toughest environments.

Comes with different array of delivery systems:

Hope Feed - 55L

Because this system is specially balanced for the maximum spray capability with

the Smoothest Finish Possible.

COLO are specialized in complete electrostatic powder coating line,curing and drying ovens,spray booth, conveyor systems, Also we are supplier of powder coating, powder filters, powder coating machine,powder coating equipment,powder coatting gun,,Reciprocator, painting guns, pumps and their equipments.

more questions,pls contact us as follow:

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content