- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

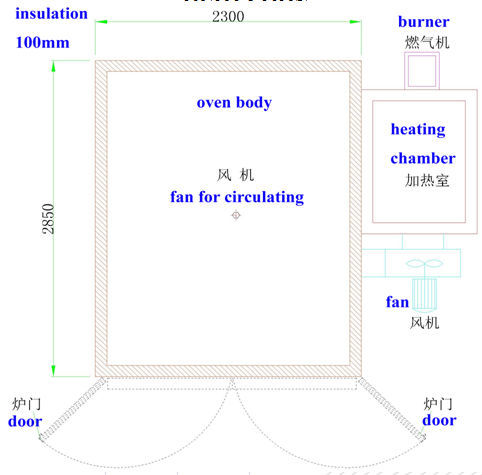

powder coating equipment line curing GAS Oven

paint coating oven ,Electrostatic powder coating oven , Gas powder coating oven,Manual powder coating oven,High quality powder coating oven.

Brief Introduction

This Powder coating oven used for curing the workpiece which has been spraying during the powder coating. When a thermoset powder is exposed to elevated temperature, it begins to melt, flows out, and then chemically reacts to form a higher molecular weight polymer in a network-like structure.

- Structure:consist of Body,insulation, cover, heater. use electricity to create the energy ,through the circulating fan ,make the temperature in the oven to rise uniformly. Then make the temperature of workpiece to rise.

built-in track to roll your powder coating racks into the ovens could be ordered together as you required.

Advantage

Low exploatation cost

Fast heating

For powder baking

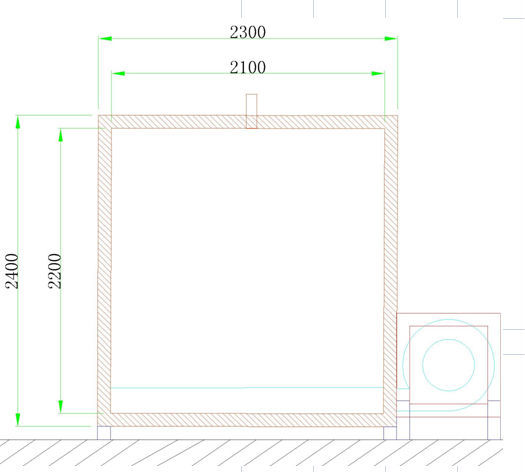

Specification

| Inner Size | L2650mm*W2100mm*H2000mm | ||||

| Outter Size: | L2850mm*W2250mm*H2400mm | ||||

| Material: | t1mm galvanized plate | ||||

| Thickness Insulation: | 100mm | ||||

| Power supply: | GAS | ||||

| Voltage: | 380v/50hz/3phase | ||||

| Door type: | Double sides | ||||

| Warm-up time: | 15 min. (180-220° C) | ||||

| Homogeneity: | < ± 3°C if 185°C | ||||

| Temperature stability: | < ± 1°C | ||||

| Temperature max. | 230° C | ||||

| Transport: | Top | ||||

| Air circulation: | Forced | ||||

| Band of burner: | Italian Riello | ||||

| Model of burner | 40 FS 10 | ||||

| burner capacity: | 100,000 KCAL (42- 116kW) | ||||

| power of motor of the burner | 0.09KW | ||||

| Total power of burner | 0.13KW | ||||

| Total powder of the oven | 3kw | ||||

| Warranty: | 12 Months | ||||

Details

consist of Body,insulation, cover, heater,electric control panel. use gas to create the energy ,through the circulating fan ,make the temperature in the oven to rise uniformly. Then make the temperature of workpiece to rise.

built-in track to roll your powder coating racks into the ovens could be ordered together as you required.

Electric Oven

| Electric Oven | |

| Inner Size | L1000mm*W1000mm*H1000mm |

| Outter Size: | L1400mm*W1200mm*H1200mm |

| Material: | t1.2mm galvanized plate |

| Thickness Insulation: | 100mm |

| Power supply: | electric (3kw) |

| Voltage: | 380V |

| Frequency: | 50-60Hz |

| Door type: | Double sided |

| Warm-up time: | 15 min. (180-220° C) |

| Homogeneity: | < ± 3°C if 185°C |

| Temperature stability: | < ± 1°C |

| Temperature max. | 300° C |

| Warranty: | 12 Months |

COLO are specialized in complete electrostatic powder coating line, paint coating plants ,curing and drying ovens, cartridge type and cyclone recovery systems, spray booth, conveyor systems, Also we are supplier of powder coating, powder filters, powder coating machine,powder coating equipment,powder coatting gun,,Reciprocator, painting guns, pumps and their equipments.

We supply: Powder spray gun spare parts Test powder coatng gun Electrostatic powder painting Electrostatic powder coating Electrostatic powder spraying machine Manual Powder Painting System Electrostatic Powder coating machine Powder painting machine Powder spray gun Electrostatic powder spraying machine Electrostatic powder coating.

COLO Powder Coating Systems is a top supplier of powder coating systems and powder coating equipment including automated powder coating machine, spray booths and spare parts for itw gema, wagner, nodrson, kci famous brand in China.

Welcome to contact with us

| Inner Size | L2650mm*W2100mm*H2000mm | ||||

| Outter Size: | L2850mm*W2250mm*H2400mm | ||||

| Material: | t1mm galvanized plate | ||||

| Thickness Insulation: | 100mm | ||||

| Power supply: | GAS | ||||

| Voltage: | 380v/50hz/3phase | ||||

| Door type: | Double sides | ||||

| Warm-up time: | 15 min. (180-220° C) | ||||

| Homogeneity: | < ± 3°C if 185°C | ||||

| Temperature stability: | < ± 1°C | ||||

| Temperature max. | 230° C | ||||

| Transport: | Top | ||||

| Air circulation: | Forced | ||||

| Band of burner: | Italian Riello | ||||

| Model of burner | 40 FS 10 | ||||

| burner capacity: | 100,000 KCAL (42- 116kW) | ||||

| power of motor of the burner | 0.09KW | ||||

| Total power of burner | 0.13KW | ||||

| Total powder of the oven | 3kw | ||||

| Warranty: | 12 Months | ||||

| Inner Size | L2650mm*W2100mm*H2000mm | ||||

| Outter Size: | L2850mm*W2250mm*H2400mm | ||||

| Material: | t1mm galvanized plate | ||||

| Thickness Insulation: | 100mm | ||||

| Power supply: | GAS | ||||

| Voltage: | 380v/50hz/3phase | ||||

| Door type: | Double sides | ||||

| Warm-up time: | 15 min. (180-220° C) | ||||

| Homogeneity: | < ± 3°C if 185°C | ||||

| Temperature stability: | < ± 1°C | ||||

| Temperature max. | 230° C | ||||

| Transport: | Top | ||||

| Air circulation: | Forced | ||||

| Band of burner: | Italian Riello | ||||

| Model of burner | 40 FS 10 | ||||

| burner capacity: | 100,000 KCAL (42- 116kW) | ||||

| power of motor of the burner | 0.09KW | ||||

| Total power of burner | 0.13KW | ||||

| Total powder of the oven | 3kw | ||||

| Warranty: | 12 Months | ||||

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content