- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

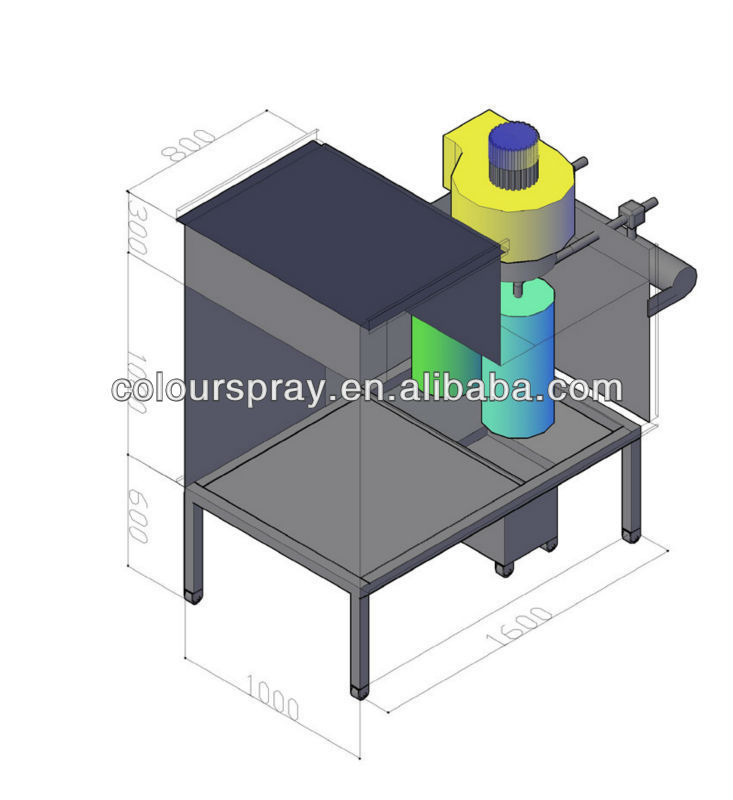

open face powder coating spray booth

Electrostatic paint spray booth

1,Full automatic control

2,Small area occupation

3,Low energy consumption

4,size is customize

5,Pulse valves and solenoids

6,Primary filter module: cartridge type

powder spray equipment ,Electrostatic powder coating booth,paint booth

The powder booth fans draw air through filters and releases it through the top of the booth. It keeps your shop nice and clean,minimizing powder dust.

1, The protection of the coating process from external influences,

joined with the keeping clean of the booth environment

2,The powder recovery

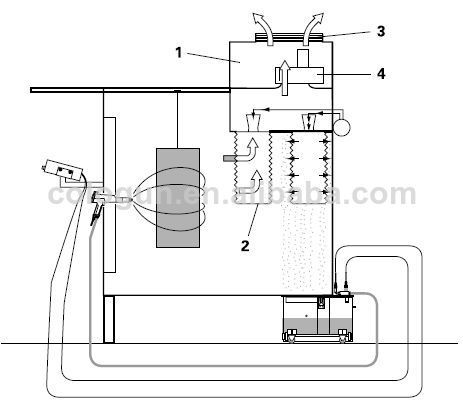

The booth function is based on a powerful exhaust air system, which

sucks air from the booth interior through filter cartridges. The resulting

negative pressure produces an airflow from the outside of the booth to

the inside, thus preventing powder from escaping into the environment.

During cleaning procedure, the powder adhering on the filter cartridges

arrives into the booth .

The cartridges are cleaned by compressed air impulses, The powder drops onto the booth floor.

The filter cleaning air is supplied from the pressure tank on the exhaust

air unit. The cleaning process and consequently the blow off duration per

filter cartridge and the pause time, before the next cartridge is blown off,

are controlled by an electronic control unit.

powder spray booth is an economical solution for basic powder coating operations requiring reclaim capability in continuous production situations.

For job shops, first-time powder coaters and to suppliment large in-house powder coating operations,this powder spray booths offer a variety of configuration options.

Booths size could Custom designed,Manual and automatic spray stations are also available. Other features include:

Durable, long-life powder-coated steel structure with high-quality galvanized canopy and floor

Low-profile booth base eliminates operator platforms

Requires only quick, easy conncet electrical and pneumatics to start production .

Fan motor is 1.5KW-5.5KW.

During operation overspray powder accumulates on the cartridge filters. As the cartridge filters load, airflow decreases and the negative pressure rises within the air handler. A timer activates a system of air purging valves that clear the cartridge filters of the accumulated powder to ensure maximum flitter life.

COLO are specialized in complete electrostatic powder coating line, paint coating plants ,curing and drying ovens, cartridge type and cyclone recovery systems, spray booth, conveyor systems, Also we are supplier of powder coating, powder filters, powder coating machine,powder coating equipment,powder coatting gun,,Reciprocator, painting guns, pumps and their equipments.

COLO are specialized in complete electrostatic powder coating line, paint coating plants ,curing and drying ovens, cartridge type and cyclone recovery systems, spray booth, conveyor systems, Also we are supplier of powder coating, powder filters, powder coating machine,powder coating equipment,powder coatting gun,,Reciprocator, painting guns, pumps and their equipments.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content