- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

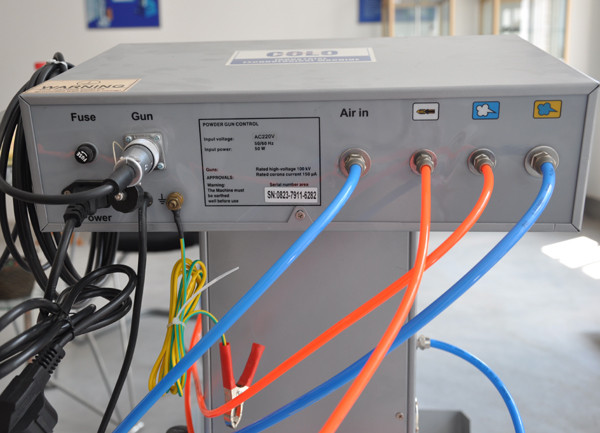

COLO-610V Box Feed Electrostatic Powder Coating Spray Unit

COLO-610V Box Feed Electrostatic Powder Coating Spray Unit

Features of COLO-610V Box Feed Electrostatic Powder Coating Spray Unit

1: excellent extraction rate, significantly reducing the amount of powder

3: New pulse plus the intelligent technologies generate static manner, maximizing the electrostatic effect

box feed unit for mutil colour changes

Description:

0-100 Digital Adjustable KV

Fully Adjustable Amperage

Pulse Power Technology for beating Faraday Cage Effect.

Able to cut Pulse Power on and off

With three setting program,for flat shape workpiece,complicated shape workpiece,recoating,easy for operation.

Fully Adjustable Air for Pump on Pressure, Dosage and Nozzle Rinsing Air.

Comes with Full Array of Nozzle Assortment.

Field Tested and Proven to operate in the toughest environments.

Comes with different array of delivery systems:

Functions

.The powder in the powder box is sucked up in the injector by the conveying air. Through the powder hose the powder air mixture reached the gun

.The powder is electrostatically charged immediately it reaches the gun nozzle.An intense field also exists between the gun nozzle and the grounded workpiece. The electrostatically charged powder sprayed onto the workpiece adheres to the latters surface.

.The converying air and the dosing air is to be requlated on the control module, the fluidizing air on the peneumatic unit.

.The powder is fluidized by forcing air from bleow truough a proous plastic plate.

| Powder Gun | |

|---|---|

| Rated output voltage | 24VDC |

| Cascade input voltage | 12V |

| Maximum output current | 180Ua(max) |

| Maximum output voltage | 0-100KV ( adjustable) |

| Maximum powder injection | 600g/min |

| Polarity | Polarity |

| Gun weight | 500G |

| Electrical Data | |

| Power range | 220V/110V |

| Frequency | 50HZ /60HZ |

| Temperature range in use | -10 ℃+50 ℃ |

| Pneumatic Data | |

| Maximum input-air pressure | 10kg/cm2 |

| Maximum input-air pressure | 6kg/cm2 |

| Minimum input-air pressure | 4kg/cm2 |

| Maximum water vapor content or compressed air | 1.4g/N m3 |

| Maximum oil vapor content of compressed air | |

COLO powder coating equipment has proven to be a reliable product requiring minimal replacement parts and servicing. At COLO, we pride ourselves on our prompt and efficient service, which can be confirmed by contacting any number of our satisfied customers. COLO guarantees its equipment and unreservedly replace any faulty equipment immediately as part of our comprehensive warranty. COLO has launched the SERIES 610 Pulse coating system Powder Coating Equipment. The design is to use pulse coating system to reduce faraday cage and the orange peel effect.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content