- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

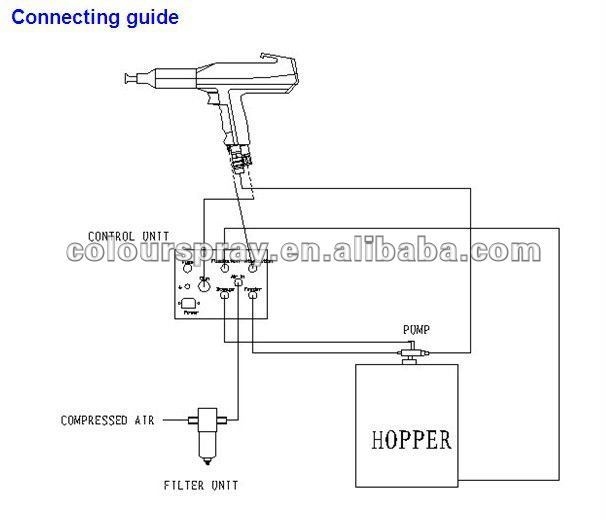

Electrostatic Powder Spraying Machine

COLO-800DT-H Manual Stand Unit Electrostatic Powder Spraying Machine

- New technology Powder feed system with air purge for faster, easier maintenance

- Variety of custom-designed nozzles provide maximum versatility and highest powder delivery efficiency, even on difficult shapes

- Pinch valve shuts off powder instantly

- Modular hopper disconnects without tools,1powder tank

- Intelligent control unit with digital display for voltage ,touch key for easy and fast operation

- DATA

Electrical data Mains input voltage 100-240 VAC Operating frequency 50-60 Hz Input power 50W Nominal output voltage (to the gun) max. 12 V Nominal output current (to the gun) max. 1 A IP54 Ambient temperature range 0°C - +40°C (+32°F - +104°F) Max. operating temperature 85°C (+185°F) Approvals CE Pneumatical data Compressed air connection 1/4" male quick release Max. input pressure 10 bar / 145 psi Min. input pressure (while unit in operation) 6 bar / 87 psi Max. water vapor content of the compressed air 1.3 g/m³ Max. oil vapor content of the compressed air 0.1 mg/m³ Packing Dimensions Length 44CM Width 44CM Height 55CM Weight approx. 21kgs Connection Description 1.1 Air In Compressed air connection (6-10 bar / 87-145 PSI) 2.1 Power Mains cable connection (100-240 VAC) 2.2 Gun Gun cable connection 1.4 Electrode rinsing air connection 1.3 Pict Supplementary air connection 1.2 Pict Conveying air connection Grounding connection Pict

- full set included:

Control unit=1set

Including:powder spray gun=1

Spare parts of gun=(round jet nozzle=2, flat jet nozzle=1 ,spray head=6,)

Powder hose(5m)=1

fluidization windpipe(6mm)=1

power cable=1

earth wire with clamp=1

fuse =2

Powder hopper=1

Including:powder injector=1

insert sleeve of injector=2

powder injector connector=1

powder tube=1

black venting tube=1

venting tube connector=1, earth wire=1

air tube (8mm)=4

air tube (6mm)=1

Trolly=1

Including:

Gun handle=1, support=1, upright column=1,wheels=4,filter unit=1

fluidization adjustment=1

The process of the coating is like this: The powder is fluidized in the powder hopper. The injectors transport the powder through the hoses to the guns. The guns spray a powder/air mixture onto the workpieces

COLO Powder Coating Systems is a top supplier of powder coating systems and powder coating equipment including manual powder coating equipment, automatic equipment, spray booths,ovens and spare parts famous brand in China.

China Powder coating gun, China powder coating machine, China powder coating system, China powder coating equipment, powder coating control unit,manual powder coating machine,manual powder coating equipment, manual powder coating gun, electrostatic powder coating equipment

welcome to contact by the following way for more information

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content