- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

powder coating unit

powder coating unit

This cup powder caoting equipment Designed for small sample testing or powder manufacturers, the Cup Unit incorporates the application cup to the gun. The cup is self-fluidizing and is easy to clean, making color changes fast and easy.

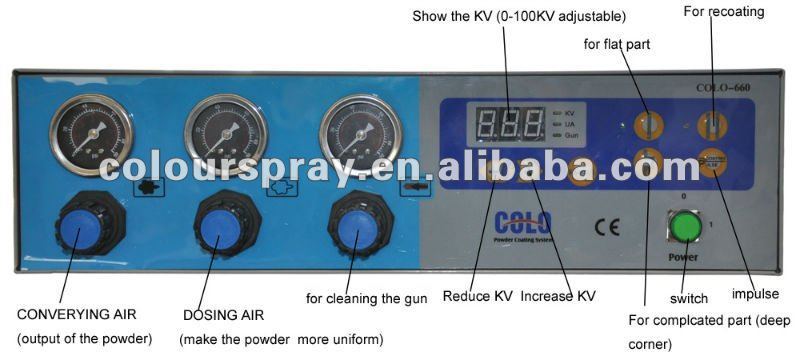

(660 series, pulse and intelligent manual operation type)

Typical characteristics:

1. Save powder by 20% compare to common Electrostatic Coating ,for the average thickness is 60 μm compare to 70 μm of the latter.

2. Can charge the powder continuously to coat well object’s deepest corner.

3. Charge the powder with low current and high voltage.

4. Reduce orange peel effect significantly compare to common Electrostatic Coating.

5. work well with powder spray booth, powder coating oven to form the whole powder coating equipment.

6.used broadly in steel coating, aluminum coating ,metal powder coating, epoxy powdercoating,polyester powder coating and bicycle powder coating ,and so on.

7,Control unit has one-touch intelligent operation button good for flat parts, complicated parts and recoat parts.Easy to operate.

Type List

COLO-660, manual type

COLO-660T-H, small production coating type (With a 10L powder hopper)

COLO-660T-C, cup unit type

COLO-660A, auto-gun type

Technical Data

Power range 110V/220v

Frequency 60HZ/50HZ

Temperature range in use -10 °C+50 °C

Powder Gun

Gun weight: ……………… 500G

Rated output voltage ……… 24VDC

Maximum output current ……… 180Ua(max)

Maximum output voltage………… 0-100KV ( adjustable)

Maximum powder injection :……… 600g/min

Polarity ……………… negative (-)

Pneumatic technical spec

Maximum input-air pressure ………….. 8kg/cm

Optimum input-air pressure…….. 6kg/cm

Minimum input-air pressure …… 4kg/cm

Maximum water vapor content or compressed air ….. 1.4g/N m3

Maximum oil vapor content of compressed air …….. 0.1ppm

Maximum cimpressed-air consumption……… 13.2 m3/h

TPulse coating ………….. ………….. ………….. 15~20 clock/sec

Included parts

| Control Unit | 1 piece |

Spray Gun | 1 piece | |

Air filter | 1 piece | |

Air blow gun | 1 piece | |

Pneumatic Hose | Some |

N.W:10KGS 4CARTON SIZE:40*40*56CM

The process of the coating is like this: The powder is fluidized in the powder hopper. The injectors transport the powder through the hoses to the guns. The guns spray a powder/air mixture onto the workpieces

China Powder coating gun, China powder coating machine, China powder coating system, China powder coating equipment, powder coating control unit

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content