- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

Que absorbe el equipo de recubrimiento en polvo de vibracion del pulso

Que absorbe el equipo de recubrimiento en polvo de vibracion del pulso

Que absorbe el equipo de recubrimiento en polvo de vibracion del pulso

1.pulse function/good effect

2.convenient color change

This model is digital display for voltage and current, enable us see the data more clearly

Pulse power technology, assuring that the corner parts and the complicated workpiece can be well-proportioned coated.

This vibration type is good for your choice, if you need to change powder frequently a day.

china powder coating Pulse spraying machine

Touch key for voltage , gun , current model change

high grade quality

nice design

with pulse coaitg system working good for corners

CE certificate

Suitable for heavy duty work

manual powder coating equipment

Quick Details:

Place of Origin | Zhejiang, China (Mainland) |

Brand Name | COLO |

Model Number | Colo-610V |

Coating | Powder Coating |

Substrate | Iron |

powder coating paint | electrostatic |

pulse function | vibrating |

size: | 68x52x84cm |

N.W | 40kg |

Feature:

vibrating style, box feed instead of powder container, shorten colour-changing time

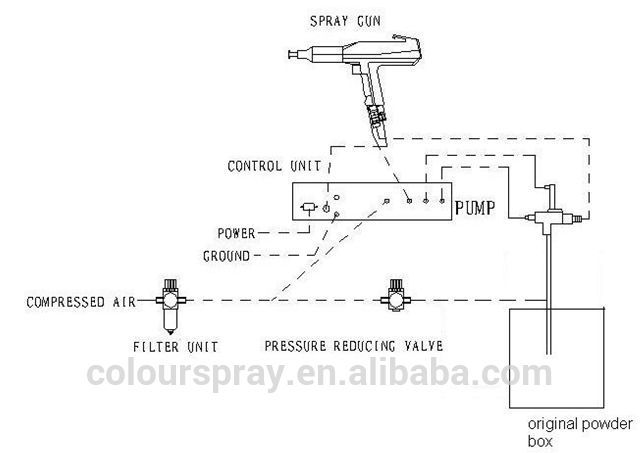

A) Control unit

Input voltage: 110V-220V

Frequency: 50-60Hz

Input powder: 50W

Pneumatic control voltage: 24V DC

Work temerature range: -5~40 centigrade

B) Compressed air data:

Max. Input air pressure: 10bar/145psi

Min input air pressure: 6bar/87psi

Max water vapour content: 1.3g/nm3

C) Powder Spray Gun

Powder yield: 600g/min

Gun powder: 550G

connection cable: 5m

→FUNCTIONS

.The fluidzed powder in the powder original box is sucked up in the injector by the conveying air. Through the powder hose the powder air mixture reached the gun

.The powder is electrostatically charged immediately it reaches the gun nozzle.An intense field also exists between the gun nozzle and the grounded workpiece. The electrostatically charged powder sprayed onto the workpiece adheres to the latters surface.

.This line voltage is converted in the control module to high –frequence current

this currents stpped up by the high-voltage transformer and the HV-cascade in the gun to 100KV and applier to the electrodes.

.The converying air and the dosing air is to be requlated on the control module , the fluidizing air on the peneumatic unit.

.The powder is fluidized by forcing air from bleow through a proous plastic plate.

.The fluidized powder gets liguld –like properties.

→Technical Data

Power range 100- 240v

Frequency 50/60HZ

Temperature range in use -10 °C+50 °C

Powder Gun

Gun weight: ……………… 500G

Rated output voltage ……… 24VDC

Input voltage …………… - 200kv

Maximum output current ……… 180Ua(max)

Maximum output voltage………… 0-100KV ( adjustable)

Maximum powder injection :……… 600g/min

Polarity ……………… negative (-)

Pneumatic technical spec

Maximum input-air pressure ………….. 8kg/cm

Optimum input-air pressure…….. 6kg/cm

Minimum input-air pressure …… 4kg/cm

Maximum water vapor content or compressed air ….. 1.4g/Nm3

Maximum oil vapor content of compressed air …….. 0.1ppm

Maximum cimpressed-air consumption……… 13.2 m3/h

TPulse coating ………….. ………….. ………….. 15~20 clock/sec

Including following parts

control unit with A trolly

control unit power supply cable

air filter

air pressure regulator

A plug-in injector

manual powder gun with gun cable,

Powder hose

rinsing air hose and standard nozzle set.

Pneumatic hoses for conveying air (red),

Supplementary air (black)

fluidizing air (black)

powder hose

Ground wire

Dimensions

Carton size:68x52x84cm G.W:37kg

powder coating gun, powder coating machine, powder coating system,powder coating equipment,powder coating control unit

The process of the coating is like this :the powder isfluidized in the powder hopper. The injectorstransport the powder through the hoses to the guns . The guns spray a powder/air mixture onto the workpieces.

COLO Powder Coating Systems is a top supplier of powder coating machine and powder coating equipment including automated equipment, spray booths and spare parts famous brand in china.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content