- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

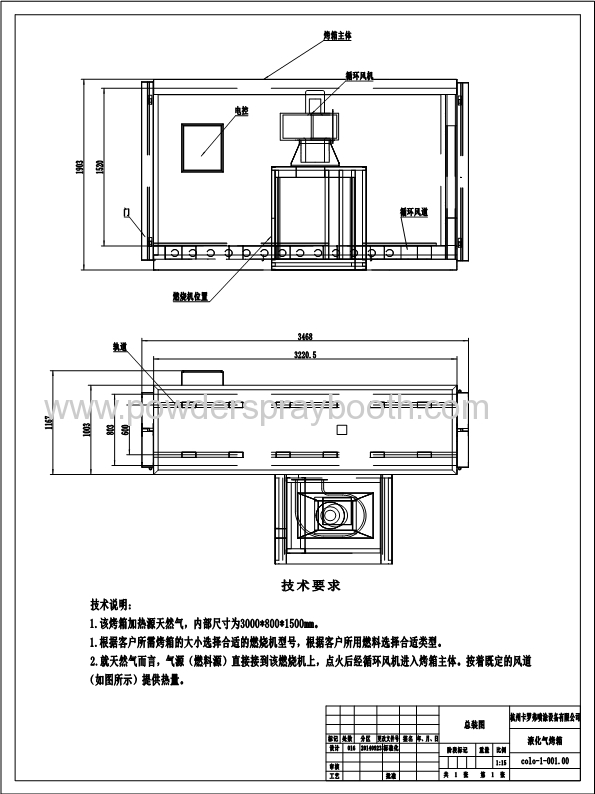

Indirect fired Gas Powder coating oven

Brief:

1,COLO powder coating ovens are designed to safely and efficiently cure previously applied powder coating media

2, Our energy-efficient designs save fuel and get to temperature quickly

3,Standard and custom sizes range from small Lab units to large heavy equipment ovens and conveyorized curing systems.

4, All our batch powder coating ovens feature premium 100mm thick insulated wall and roof panels.

COLO-0813 is a LPG fired powder coating oven.

the feature as follow:

1,Precise temperature control, furnace tolerance

of +/- 5 degrees Celsius. Indirect heating

system with a heat exchanger

2,Hot air is transferred from the bottom up.

3,Heat exchangers used in seamless

steel tubes 8x8 array, use the

combustion liner 310S

stainless steel seamless

pipe thickness of 3-4mm.

4,Closed-round clean efficient

heat circulation system

the controller

with the trolley

The technical data:

Model | colo-0813 |

Worksize dimensions | 800 width x 1500 height x 3000 depth |

Overall dimensions | 1200 width x 1900 height x 3500 depth |

Power supply | LPG |

Voltage/Frequency | 380V(50-60hz) |

Warm-up time | 15-30 min. (180° C) |

Temperature stability | < ± 3.0-6°C |

Temperature max. | 250° C |

Burner | Italy Riello, 10,0000cal |

Circulation/ Air flow | Vertical ,Variable through holes on the walls |

Ventilation performance | 1131-2565m3/h |

Motor power | 1.5kW |

Warranty | 12 months |

The drawing:

This Powder coating oven used for curing the workpiece which has been spraying during the powder coating. When a thermoset powder is exposed to elevated temperature, it begins to melt, flows out, and then chemically reacts to form a higher molecular weight polymer in the surface of the workpiece.

Application:

used for the powder coating and line, plant

Shipping:

can ship to any port from Ningbo or Shanghai by sea.

Packing: proper packing suitable for container loading

Services: we supply all equipments about the powder coating, such as booth, oven, reciprocator, gun, line, semi-line and plant.

About us:

Installation in customer's factory

We have many years experiences on powder coating. We are a typical Chinese supplier and specialized in the research, development and production of powder spray booths, powder coating oven,powder coating gun,powder coating line. We insist in offering superior quality products and efficient service.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content