- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

Mono-cyclone+ after filters recovery system powder coating spray booth

custom sizes powder recovery systems,ideal fast color change powder coating booth,Mono-cyclone+ after filters recovery system powder spray booth

for large mass production

automatic powder coating lines

CE approved

Mono-cyclone+ after filters recovery system powder spray booth

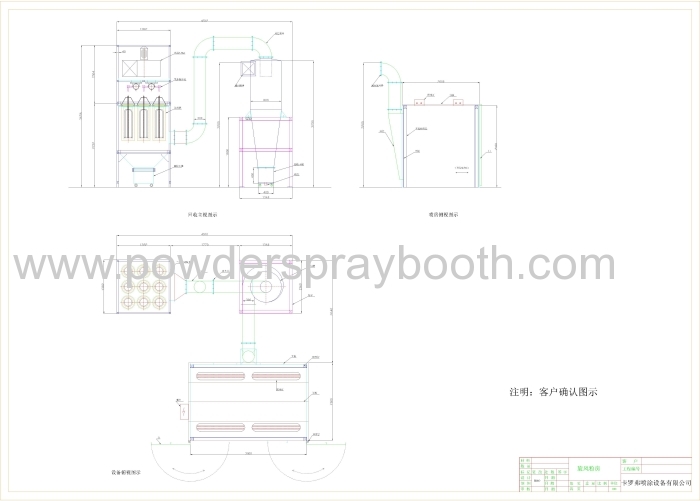

drawing :

1,Powder spray booth body

Various range of industrial powder spray booths is based on a modular concept, which enables each booth to be customized to suit any specific requirement. The size of the Manual & Automatic Booth is determined by the size, the speed and the shape of the objects to be coated. The high efficiency recycle system recovers as much as 98% plus of the powder exhausted from the booth.

Data of this spray booth:

| Booth Type | Mono cyclone |

| Operator dimensions | 3000width x 2000 height x 1500 depth (1PC) |

| Overall dimensions | 3200width x 2200 height x 2000 depth |

| Weight | 1000kg |

| Power supply | Electric |

| Nominal power | 7.5kW |

| Voltage | 380V |

| Frequency | 50-60Hz |

| Filters | Polyester |

| Filters count | 9 |

| Filters hang type | easy for change |

| Filter cleaning system | Pneumatic |

| Warranty | 12 months |

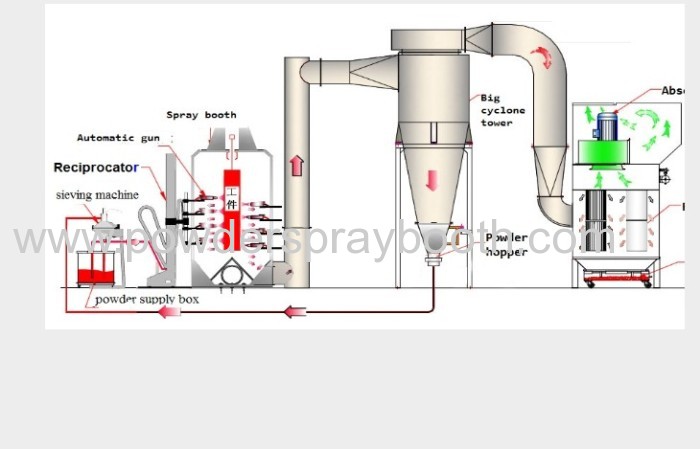

2,recovery system:

extruded air and is forced spirally downwards by centrifugal force, sieved and brought back to the powder hopper by a powder pump. The working principle is based on centrifugal effect

other cyclone powder spray booth ,pls check as follow:

The COLO Mono-cyclone has a specially constructed shape. It is conical from top to bottom. The entry and the top part of the cyclone have been designed so as avoid the necessity to clean, even with extreme colour changes. Additionally, the cyclone achieves a very high degree of effectiveness due to the unconventional shape. On the bottom part of the cyclone, a pneumatic powder recovery system is attached. The stand-alone system consists of a sieving device, peristaltic conveyor unit with control and cleaning unit. The recovered powder is brought back to the powder centre by the peristaltic conveyor.

Shipping:

can ship within 30 days .

Packing: proper packing suitable for deliver

Services: we supply all equipments about the powder coating, such as booth, oven, reciprocator, gun, line, semi-line and plant and spare parts.

About us

We have many years experiences on powder coating equipment. We are a typical Chinese supplier and specialized in the research, development and production of powder spray booths, powder coating oven,powder coating gun,powder coating line. We insist in offering superior quality products and efficient service.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content