- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

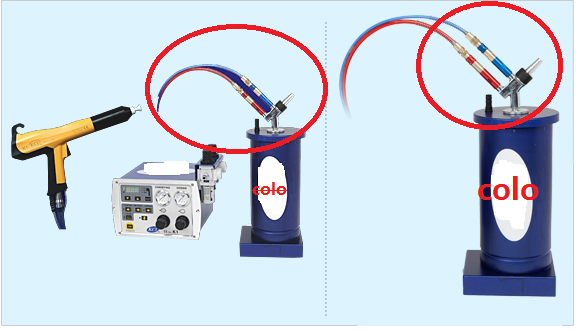

K1 powder injector IJ9000

K1 powder injector IJ9000

The powder injector is used to convey normal organic powders betweenthe powder hopper and the powder gun.

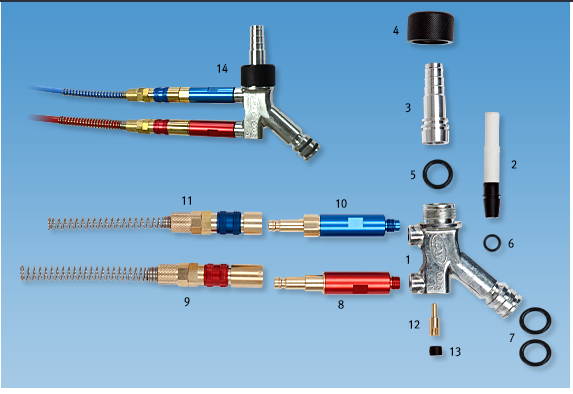

Components of K1 powder injector IJ9000

Drawing No. | Q'ty | Description | Specification |

1 | 1 | Injector Body | 79×75×20 |

2 | 1 | Insert Sleeve | φ13×70 |

3 | 1 | Sleeve Holder | φ19×53.7 |

4 | 1 | Sleeve Holder Nut | φ30.8×19 |

5 | 1 | O-Ring | φ12×1.5 |

6 | 1 | O-Ring | φ8.5×1.5 |

7 | 2 | O-Ring | φ11.8×2.4 |

8 | 1 | Conveying Air Connector | QCM1/8-φ8 |

9 | 1 | Conveying Air Coupler | QCφ8 |

10 | 1 | Dosing Air Connector | QCM1/8-φ6 |

11 | 1 | Dosing Air Coupler | QCφ6 |

12 | 2 | Injector Nozzle | 22×φ6.8 |

13 | 3 | Nut | 1/4 |

14 | 1 | Injector Unit | 30×115×150 |

Apply to powder coating equipment

Principle of K1 powder injector IJ9000 and influence of supplementary air

If air flows through the nozzle into the cavity, a vacuum is created in thecavity (see figure below).

This vacuum causes powder to be drawn upthe suction tube and into the cavity. A powder/air mixture is created.

Theforward air velocity at the nozzle conveys the powder/air mixture throughto the powder hose to the gun.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content