- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

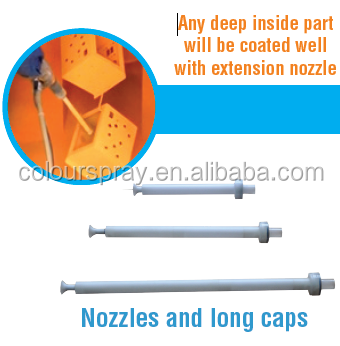

Electrostatic coating gun with extension nozzle

Application of Electrostatic coating gun

The Manual powder coating gun is built exclusively for the electrostatic coating with organic powders.

The extremely light Manual powder gun with integrated high voltage generation can produce optimum penetration

and high charging efficiency. The gun is detachable, therefore easy for maintenance and repair.

Technical data

Electrical data

- Mains input voltage 100-240 VAC

- Operating frequency 50-60 Hz

- Input power 50W

- Nominal output voltage (to the gun) max. 12 V

- Nominal output current (to the gun) max. 1 A

- IP54

- Ambient temperature range 0°C - +40°C (+32°F - +104°F)

- Max. operating temperature 85°C (+185°F)

- Approvals CE

Pneumatical data

- Compressed air connection 1/4" male quick release

- Max. input pressure 10 bar / 145 psi

- Min. input pressure (while unit in operation) 6 bar / 87 psi

- Max. water vapor content of the compressed air 1.3 g/m³

- Max. oil vapor content of the compressed air 0.1 mg/m³

Packing Dimensions

| Length | 120CM |

| Width | 79CM |

| Height | 73CM |

| Weight | Approx 55kgs |

Spare parts of Electrostatic coating gun

Note: When order, pls list the item No.

The Manual coating equipment with the Electrostatic coating gun

Manual coating equipment-structure

1 control unit 2 Manual powder gun

3 injector 4 Mobile frame with hand rail (trolley)

5 Fluidized powder hopper 6 Powder filler flap

7 Swivel wheel 8 Filter unit

9 Gun holder 10 Shelf

11 Hose holder 12 Hose holder

13 Rubber wheel

Drawing connection of the Manual powder coating gun

The process of the coating

The process of the coating is like this :the powder is fluidized in the powder hopper. The injectors transport the powder through the hoses to the guns . The guns spray a powder/air mixture onto the workpieces.

Powder coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin". The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as "whiteware," aluminium extrusions, and automobile and bicycle parts. Newer technologies allow other materials, such as MDF (medium-density fibreboard), to be powder coated using different methods.

The powder coating process involves three basic steps:

Part preparation or the pre-treatment

The powder application

Curing

Colo is the best brand in China with Professional team, which can provide Excellent service.

1. All requirements for powder coating can be meeted, namely designing, manufacturing, assembling, commissoning and training.

2. All equipments for powder coating can be provided, like powder coating machines, powder coating guns and related spare parts,spray booths, curing ovens, reciprocators, powder coating lines.

3. Technical support for all kinds of powder coating line,manual or semi-auto or full auto lines.

Colo has exported to more than 90 countries, such as Mexico, Colombia, Peru, Canada, the United States, Brazil,

Russia, Poland, France, Germany, Italy,Egypt, Vietnam, India, Saudi Arabia, South Africa and other countries. We have

built good long-term relationship with our customers. They come to visit our factory from time to time.

Colo is the leading powder coating equipment manufacturer in China, which provides high quality equipments

to more than 90 countries all oven the world with advanced manufacturing machines and professional

technicans. Colo offers a wide range of power coating equipments, namely powder coating machine, power

coating gun, spray booth, curing oven, automatic powder coating applicator, powder coating line and

replacement of spare parts for the famous brand in the world.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content