- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

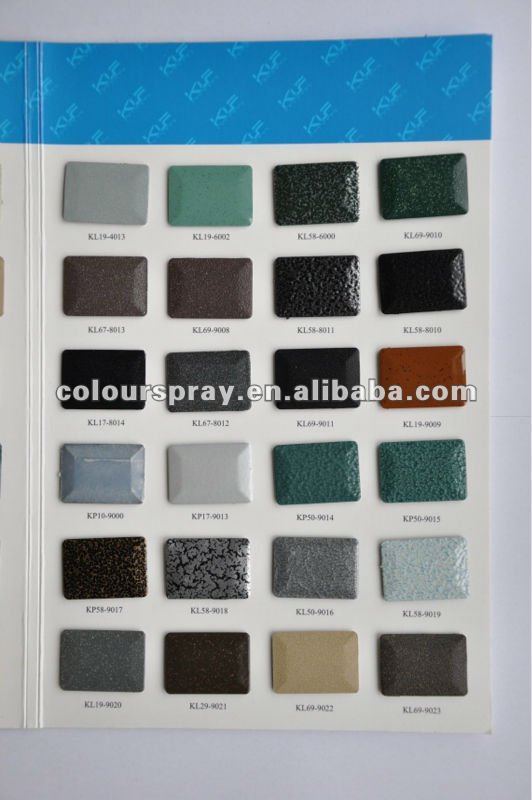

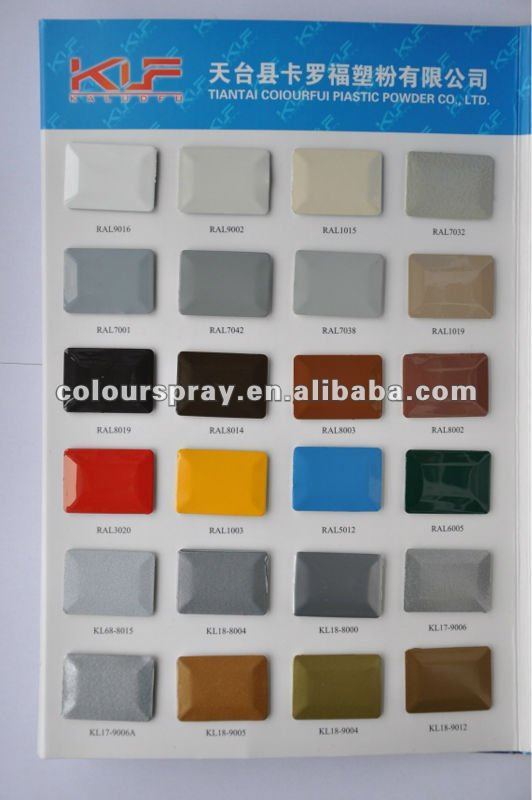

Electrostatic epoxy powder coating

Electrostatic epoxy powder coating

We are a professional supplier of powder coating and we worked in this field for many years

we provide many kind of powder paint, like a hammer, orange lines, grinding, highlights and inferior smooth, crack, flash of gold, silver and other effects, have appeared in recent years, high temperature resistant powder coating powder, powder painting at low temperature, high weather resistance, water resistance, acid powder powder powder, low temperature curing, UV curing powder powder and so on

Property:

Properties | Test Method | Value |

Pencil Hardness | GB/T 6739-1996 | ≥ H |

Impact strength test | GB/T 1732-93 | 50 KG cm |

Erichsen cupping | GB 9753-88 | >6mm |

Adhesion | GB/T 9286-1998 | 0grade |

Bend test | GB 6742-86 | 3mm |

Salt spray test | GB/T 1771-91 | 100h no change |

Humid heat test | GB/T 1740-79 | 1000h ≤ 1 grade |

Accelerated light aging test | ASTM G154 | QUV 0.78m/m2 340nm 500h |

Applying Condition: Pretreatment:Phosphated Chromated

Coating method:Electrostatic-fluidized bed coating;Corona electrostatic spray coating;Tribo-electrification coating

Curing condition: 200°C/10min or 180°C/15min or 160°C/20min

Packing: Double pvc bag,net weight is 20KG each carton

Storage: Dry room with good ventilation, Temperture is lowder than 30°C,avoid direct

sunlight.There are 12 months to maintain under this condition.Expired prod

ucts still cannot be used unless testing results meet the utilization standards

Health and Safety: There are no hazardous ingredients in all the raw materials of powder coatings

and no hazardous gas will be released while using.However,the inhalation of

dusts should be avoilded.An operator should wear an anti-dust mask and try

best to avoid long-term contact with the powder coating.Those coaings sticked

on the skin should be washed by soap

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin". The powder may be a thermoplastic or a thermosetpolymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as "whiteware," aluminium extrusions, and automobile and bicycle parts. Newer technologies allow other materials, such as MDF (medium-density fibreboard), to be powder coated using different methods.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content