- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

Electrostatic painting line aluminium profile powder coating application

Description of Electrostatic painting line aluminium profile powder coating application

1. Name of workpiece: Aluminium profile (Horizontal hanging method)

2. Max hanging size on each hanger: L6300mm×W200mm×H1500mm

3.Suggested interval between 2 hangers: 500mm

4. Conveying speed: 1.3m/min

5. Output: 10-12 hangers per hour

6. Spraying method: 4 auto spray guns (match on 2 reciprocators) & 2 manual spray guns

7. Heating source: natural gas (Other choices are available: electricity, oil or coal)

8. Required plant size: L52m×W24m×H6.5mm

Description of Electrostatic painting line aluminium profile powder coating application

1. Name of workpiece: Aluminium profile (Horizontal hanging method)

2. Max hanging size on each hanger: L6300mm×W200mm×H1500mm

3.Suggested interval between 2 hangers: 500mm

4. Conveying speed: 1.3m/min

5. Output: 10-12 hangers per hour

6. Spraying method: 4 auto spray guns (match on 2 reciprocators) & 2 manual spray guns

7. Heating source: natural gas (Other choices are available: electricity, oil or coal)

8. Required plant size: L52m×W24m×H6.5mm

Powder Coating Production line includes:

1. Pre-treatment system : Automatical Spraying pre-treatment and dipping pre-treatment are available;

2. Drying oven : Drying oven which drying the water after pre-treatment is designed according to

custmoer actual conditions.

3. Powder coating spray system: Auotmatic spray reciprocator, Maunal spray equipment and Semi-

auto (Auto-spraying with manual reparing spraying) are for your choice;

4. Powder recycling system: Cyclone equipment and cartritdge filters is customized and introduced

according to actual requirement by customer;

5. Curing oven : Tunnel curing oven, bridge type curing oven, Electric power heating curing oven,

Gas-heating curing oven, Diesel heating curing oven, High temperature, lower temperature curing

oven is available for fitting your sole factory.

6. Conveying system: Various design according to different requirement by customer on the basis of

customers' workpiece and output information.

Powder Coating Line custom made:

If you want to custom made any powder coating line,pls tell us the following specifications:

1. The size of workpiece,especially the max size

2. The max weight of the workpiece

3. Is there any requirements about the suspension of the workpiece?

4. The material of the workpiece

5. The anticipative output for the biggest size of the orkpiece(how many pcs in 8 hours)

6. The length,width and height of the factory available for the powder coating line

7. The heating power:Liquefied Petroleum Gas, Liquefied natural gas,diesel,or electric?

8. Do you need to change colors every day? How many colors do you have in total?

9. Do you need automatic painting or manual painting?

10. Do you need pre-treatment process? If you do,you like spray pre-treatment or bath pre-treatment?

11. The local electricity conditions(_V/_Phase/_Hz)

12. Do you have any special requiremnts about the package?

Installation of Powder Coating Line for customer in Russia

Various application of Colo powder coating line

Colo is the best brand in China with Professional team, which can provide Excellent service.

1. All requirements for powder coating can be meeted, namely designing, manufacturing, assembling, commissoning and training.

2. All equipments for powder coating can be provided, like powder coating machines, powder coating guns and related spare

parts,spray booths, curing ovens, reciprocators, powder coating lines.

3. Technical support for all kinds of powder coating line,manual or semi-auto or full auto lines.

Company Information:

1,products sample

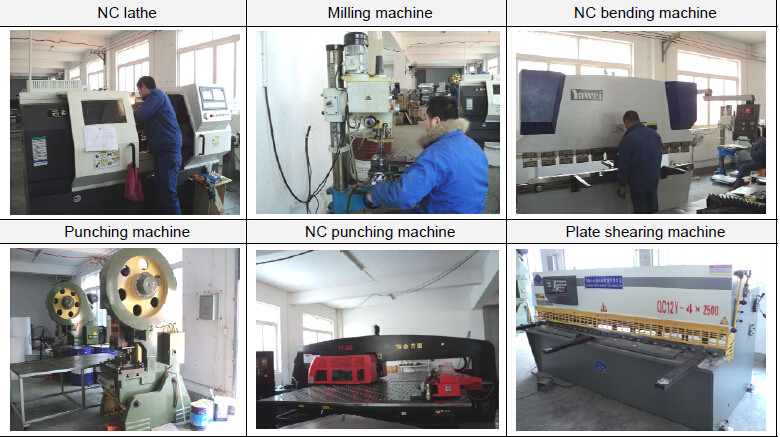

2,machines

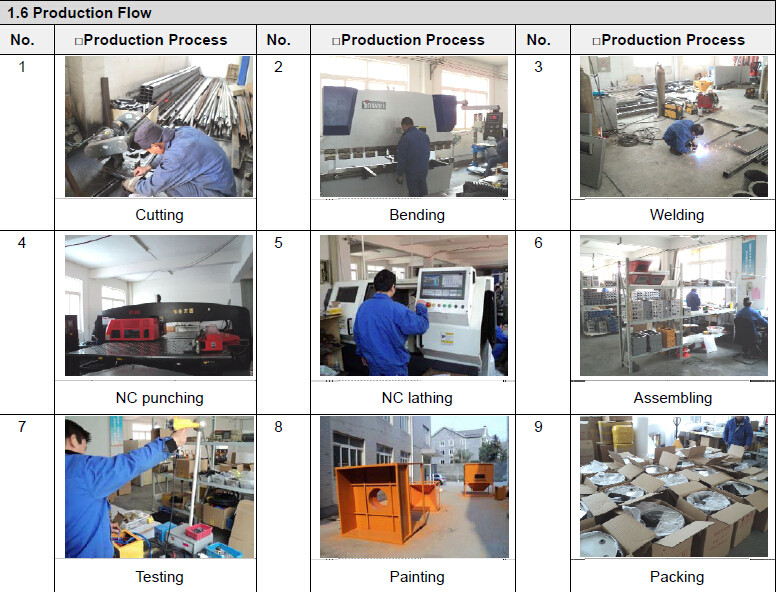

3,production flow:

Customer Visting:

powder coating gun, powder coating machine, powder coating system,powder coating equipment,powder coating control unit

COLO are specialized in complete electrostatic powder coating line, paint coating plants ,curing and drying ovens, cartridge type and cyclone recovery systems, spray booth, conveyor systems, Also we are supplier of powder coating, powder filters, powder coating machine,powder coating equipment,powder coatting gun,,Reciprocator, painting guns, pumps and their equipments.

More information,welcome to contact us as follow:

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content