- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

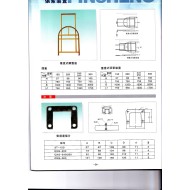

- bo'x feed

Powder coating oven 40 FS series single-stage gas burner

Powder coating oven 40 FS series single-stage gas burner

RIELLO 40 FS series single-stage gas burners, is a complete range of products developed to respond to anyrequirements of light industrial applications. RIELLO 40 FS series is available in five different models, from11 to 220 kilowatts, is divided into four different output configurations. All models are designed to use the column slightlyRIELLO 40 FS series of the same components. High quality guarantee safe working level. TheRiello 40 Financeburner is equipped with a microprocessor - based flame control panel, with diagnostic functions. In developing these burners, special attention to reducing noise, to ease the installation and adjustment, in order to obtain the smallest possible size to fit any sort of boiler market. All models have passedthe European EN 676 standard, in line with European directives for EMC and low voltage, mechanical and boiler efficiency.

we can supply burners, boiler burner accessories and other products

Curing oven combustor

Curing oven

Structure:consist of Body,insulation, cover, heater. use gas to create the energy ,through the circulating fan ,make the temperature in the oven to rise uniformly. Then make the temperature of workpiece to rise.

Built-in track to roll your powder coating racks into the ovens could be ordered together as you required.

Model | COLO-O-1 |

Overall dimensions | 1500 width x 1700 height x 3000 depth |

Power supply | GAS |

Voltage | 110V/220V |

Frequency | 50-60Hz |

Door type | Double sided, drive-through |

Warm-up time | 15 min. (180-220° C) |

Homogeneity | < ± 3°C if 185°C |

Temperature stability | < ± 1°C |

Temperature max. | 230° C |

Transport | Top |

Air circulation | Forced |

Band of burner | Italian Riello |

Capacity | 7650L |

Warranty | 12 months |

Colo is the best brand in China with Professional team, which can provide Excellent service.

1. All requirements for powder coating can be meeted, namely designing, manufacturing, assembling, commissoning and training.

2. All equipments for powder coating can be provided, like powder coating machines, powder coating guns and related spare parts,spray booths, curing ovens, reciprocators, powder coating lines.

3. Technical support for all kinds of powder coating line,manual or semi-auto or full auto lines.

COLO Powder Coating Systems is a top supplier of powder coating systems and powder coating equipment including automated powder coating machine, spray booths and spare parts famous brand in China.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content