- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

Small scale metal powder coating spray booth

Feature:

this new powder coating booth with PLC controller,coul control the powder coating booth more accurate.we could provide you the powder coating booth that will fit your needs. the powder coating spray booth fans draw air through filters . as the cartridge filters load,air flow decreases and the negative pressure rises within the air handler. a timer activates a system of air purging valves that clear the cartridge filters of the accumulated powder to ensure max filter life.

Durable, long-life powder-coated steel structure with high-quality galvanized canopy and floor

Low-profile booth base eliminates operator platforms

Requires only quick, easy conncet electrical and pneumatics to start production

The PLC controller

the hanger

The technical data:

| Model | COLO-S-1517 |

| Booth Type | Closed |

| Operator dimensions | L1500*W1000*H1700mm |

| Overall dimensions | L1600*W2000*H2250mm |

| Weight | 150kg |

| Power supply | Electric |

| Nominal power | 2.2kw |

| Voltage | 380V |

| Frequency | 50-60Hz |

| Filters | Polyester |

| Filters count | 2 (325*900) |

| Filters hang type | easy for change |

| Filter cleaning system | Pneumatic |

| Air consumption | 4000m3/h |

| Warranty | 12 months |

Installation

1.Install the ground should be flat, smooth landing foot machine,ventilator machine feet should be firmly fixedto the ground

2.spray booth enclosure must be grounded. Grounding Methods:Ф10 mm roundlong 1.5-2mmintothe ground, exposed 10 mm,the solder terminals,with 4 mm 2 wire connection tothe spray booth and the electrostatic generator grounding stud

3.Fitted withfilters,elastic fit.

4.Intake pipe connected to the air supply, close the drain valve

5.switch box connected to the power supply, connect the power electrostatic generator

6.Start the exhaust fan button to check the motor rotation is correct

7.Compressed air must pass through an air purifier to remove oil and water, the water content of less than1g/m3

Application:

is an economical solution for basic powder coating operations requiring reclaim capability in continuous production situations. powder booth is one of the most critical components of the product finishing process.

Booths size could Custom designed,Manual and automatic spray stations are also available.

Company Information:

1,products sample

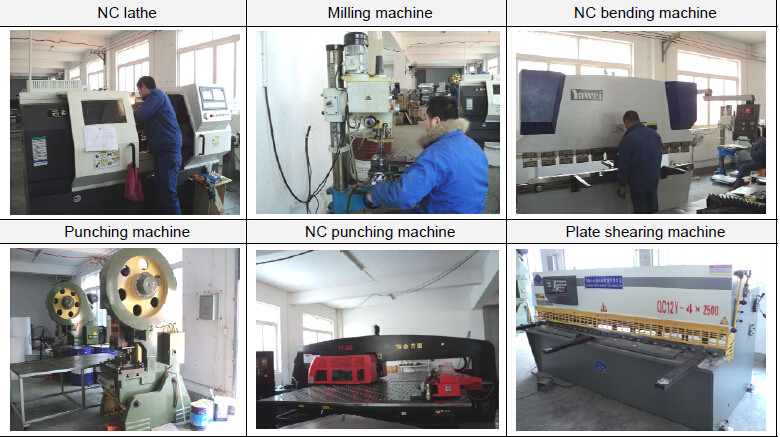

2,machines

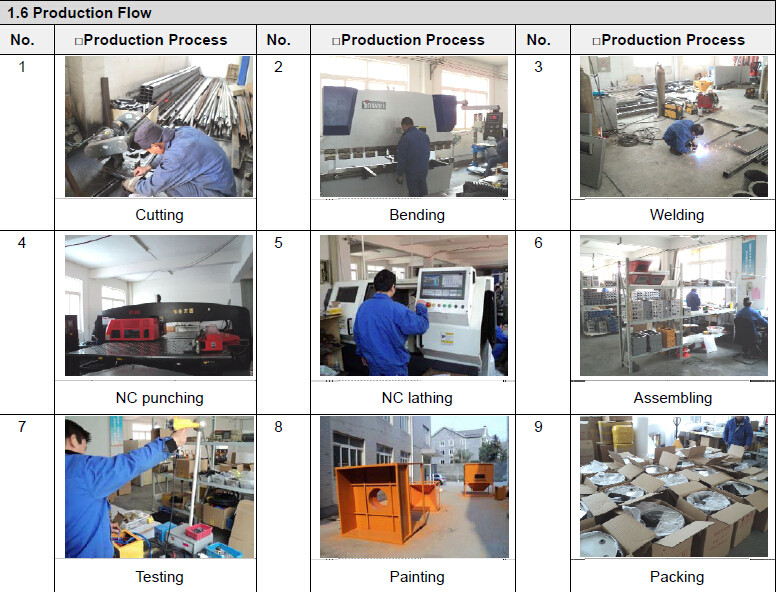

3,production flow:

Customer Visting:

COLO Powder Coating Systems is a top supplier of powder coating systems and powder coating equipment including automated equipment, spray booths and oven and spare parts for famous brand in china.

powder coating gun, powder coating machine, powder coating system,powder coating equipment,powder coating control unit

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content