- Powder Coating Gun

- Powder Coating Booth

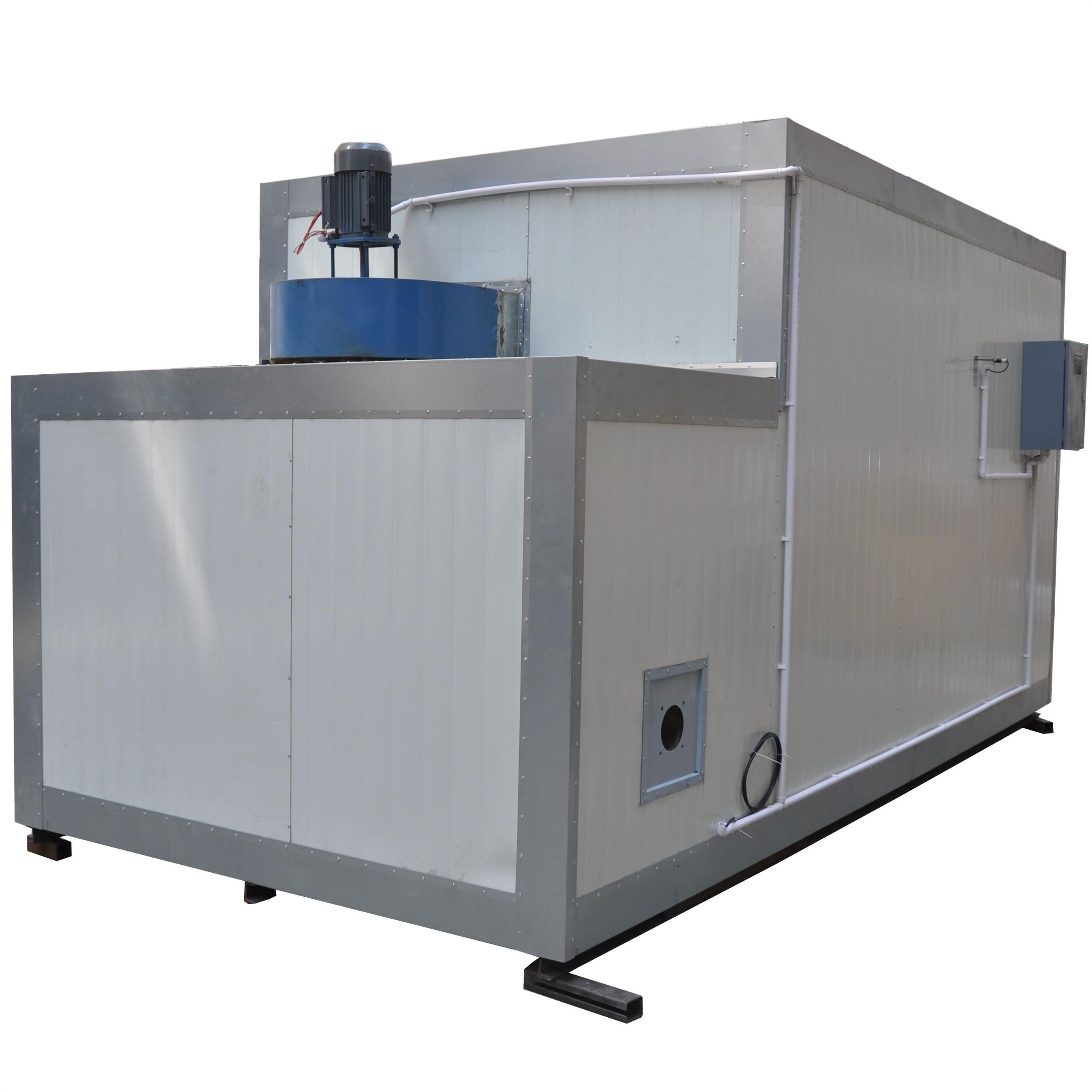

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

Gas powder coating curing oven

Description of Gas powered furnace powder paint curing oven

Our powder coating ovens are designed to safely and efficiently cure previously appliedpowder coating. COLO’s Oven with immediate delivery available on selectsizes.

Our energy-efficientdesigns save fuel and get to temperature quickly. Standard and custom sizes range from small walk-in units to large heavy equipment ovens and conveyorizedcuring systems. Options include conveyor or cart system integration.

All our batch powdercoating ovens feature premium 100-150mmthickness rock wool insulation wall and roof panels,specially shaped seal does not contain asbestos and is safe for the user

ovens Heater control is based on a microprocessor, which each time is programmed to meet yourexpectations. Control provides high precision heating process, it offers allthe features you need.

ovens with forced aircirculation, with a very good temperature uniformity result, our research hasshown that the uniformity of air temperature in the furnace of our circuit doesnot exceed ± 3 ° C!

Riello or Baltur burner from Italy

Feaures

- Patented internal high volume duct system

- Walls and roof comprised of galvanised steel plates with high-density Rockwool insulation at 100mm thick.

- Our advanced design and high quality manufacturing process leads to remarkably low running costs

- Powerful centrifugal fans and our patented high volume internal duct system allow highly efficient running and give an even heat throughout.

- Our ovens are controlled by a PLC control panel. This allows accurate cure timing and helps improve fuel efficiency.

- High quality burners – tried and tested over many years

- Internal escape mechanism

- Flat packed for easy transportation and installation

- Each oven is built and tested before shipping. The test includes: Heat distribution check to eliminate any hot or cold spots, correct air/gas mixture to eliminate carbon monoxide gases and to ensure economical running. We also check the internal escape mechanism.

- CE mark

- Fully guaranteed

- Service contracts available

- Optional insulated floor is comprised of 100 mm thick layer of insulated fibres and a steel plate cover, which allows trolleys to be used to carry products in and out of the oven.

Specification

Worksize dimensions 2000mm width x 2000mm height x 5000mm depth

Door type Double sided, drive-through

Power supply Gas/LPG/Diesel

Voltage/Frequency 380V/220v(50-60hz)

Warm-up time 15-30 min. (180-220° C)

Homogeneity < ± 3°C if 185°C

Temperature stability < ± 1-3°C

Temperature max. 250° C

Ventilation performance 805-1677m3/h

Transport Top

Air circulation Forced

Capacity 20000L

Warranty 12 months

Colo is the best brand in China with Professional team, which can provide Excellent service.

1. All requirements for powder coating can be meeted, namely designing, manufacturing, assembling, commissoning and training.

2. All equipments for powder coating can be provided, like powder coating machines, powder coating guns and related spare

parts,spray booths, curing ovens, reciprocators, powder coating lines.

3. Technical support for all kinds of powder coating line,manual or semi-auto or full auto lines.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content