- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

compact powder coating plant for aluminium profile

compact powder coating plant

compact powder coating plant video

compact powder coating plant

https://www.youtube.com/watch?v=LtQYojqgnnI

The palnt is made of :

1,Dry oven

2,Powder coating system

3,double conveyor

4, electrical control board

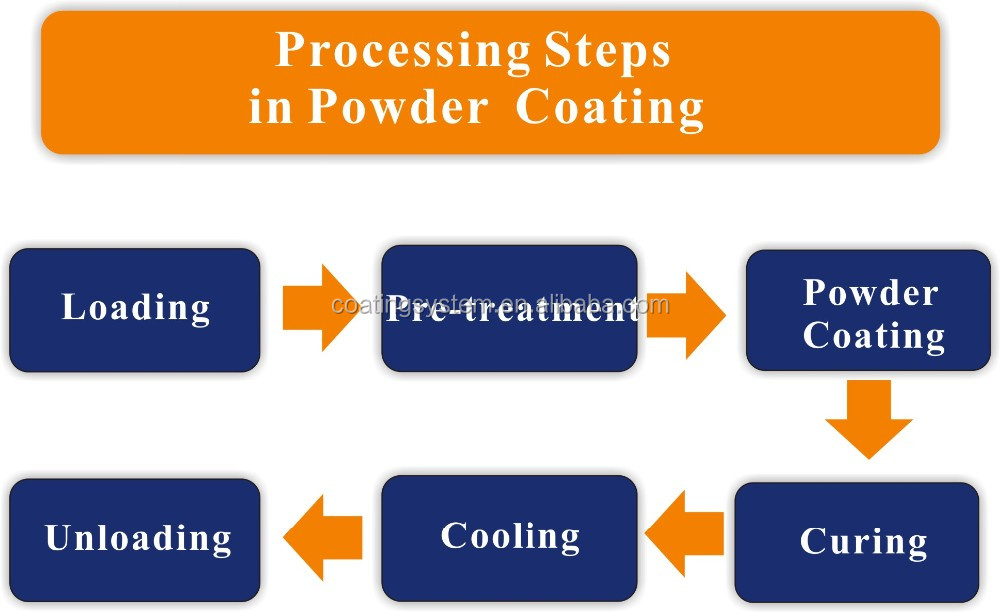

Powder coating line process:

The Automatic Powder Coating Line Including The Following Six Parts:

Part One Pretreatment System

Here by pretreatment, we mean metal pretreatment as the powder coating is predominantly applied to metals.

Pretreatment is the base for powder coating. It is said that you can not make a good coating work with poor pretreatment.

The powder coating pretreatment include mechanical or chemical:

Mechanical cleaningincludes methods like scratch brushing and sand blasting.

Chemical cleaningincludes removal of dirt, oil and grease.

Engineer in COLO will analyze your requirements to design different pretreatment system for you. Include sandblasting, spraying system or immersing.

Part Two Drying System

The drying system is for drying the wet workpiece after pre-treatment, It is design according to different requirement. The temperature about 100 degree centigrade for 10-15 mins.

Part Three Powder coating booth with powder recovery system

Our powder spray booth is easy to clean, resulting in a quick color change and is safe to operate. No powder spillage out of the booth .

The powder recovery system could be multi-cyclone, Mono-cyclone and filters.

Material of the powder spray booth could be plastic, stainless steel, powder coated carbon steel

Part Four Electrostatic powder coating spray gun

The electrostatic powder gun manufacture in COLO with high powder adhere to the workpiece, reduce the powder waste. COLO developed the new technology in powder coating gun every year.

Part Five Powder Curing system

Curing oven could make as tunnel curing oven and bridge powder curing oven. With temperature 180-200 degree centigrade for 15-20mins. Energy could be electric, natural gas, or diesel.

Part Six Conveyor system

According to different weight produce and the requirements of customer, COLO engineers will select different type conveyor . could be close circuit continue conveyor ,line conveyor or power and free conveyor as .

Upload and down load:

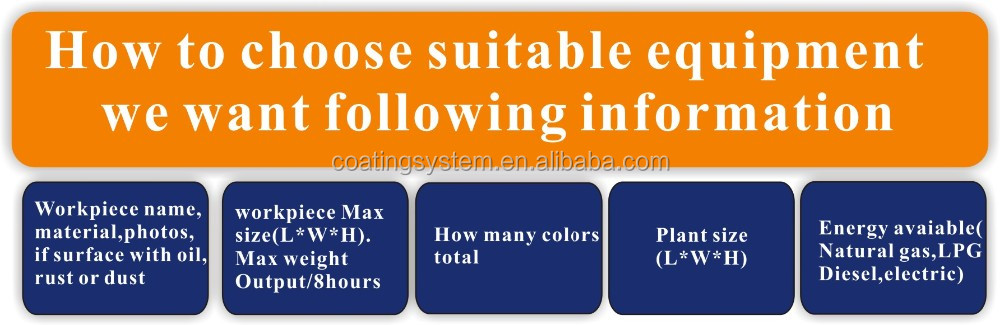

hope to know the information as follow for designing powder coating plant

Our experienced team is waiting for you here :

Our Customers:

Customers from more than 100 countries,thank you for choose powder coating equipments from COLO.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content